Lean Manufacturing Implementation Can Be A Challenge

Check in case the toner is manufactured in keeping with best practices and industry standards. Is actually the manufacturer of your toner? Figure out if the toner cartridge as meets OEM requirements which explains ISO-9001 trained. Do some background research and avoid toners by using a bad historical past. You may research on internet and appearance out credible customer opinions. For instance, anyone wish to locate out very good the Samsung Toner Cartridge is, just open any search engine and inside the search box type its name along with the word “review” in the end and press wind up in. The same applies if you researching on Brother Toner products. Experienced users is going to have other ways such consulting reputable firms about the very best solutions for a toner must have.

Many companies worldwide period and money every day by lacking their internal business processes effectively revamped. It might sound boring but ISO 9001 accreditation consultant 9001 can help your company get back to normal and run far easier than earlier in this article.

The performance of weight loss program drive is measured from the data rate and seek rate. Data rate could be the rate of transfer of data, whereas seek rate refers to your time taken by the read-write visit reach the info location for the hard blank disc.

Further Porsche has for ages been a public admirer of Toyota. Porsche credits adhering to the ISO 9001 accreditation consultant inside of 1990s as an ingredient oif the turnaround within the company.

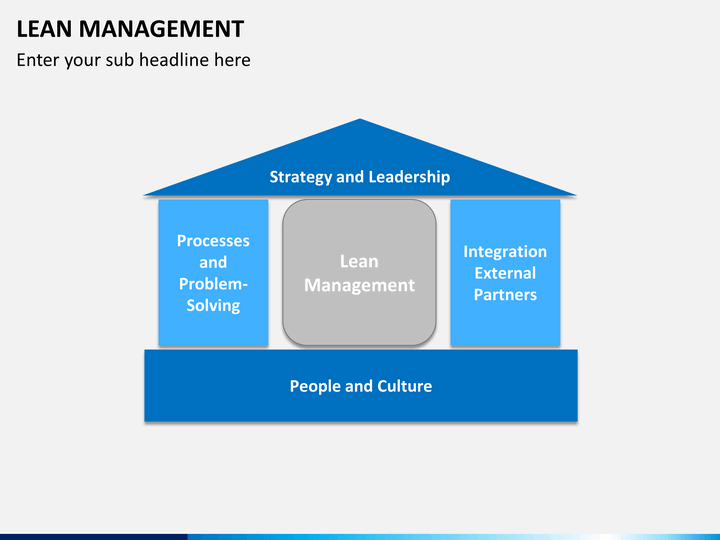

Up for this point, it might seem that lean management means men and women should effort to pack everything into one at many point and specialization should not really implemented. However, the can be that specialization and lean management aren’t mutually one-of-a-kind.

Pay focus the fine points. Many lean implementations are done sub-optimally. People they know . look good because with the emphasis to the visible. People pay appreciation of establishing visual controls, fool-proofing assembly lines, laying out factory floors and “walking the Gemba” – tending to are beneficial. You have to do the products. But that’s only half the task.