Grab Eyeballs With The Very Quality Prints From Eazy-Print

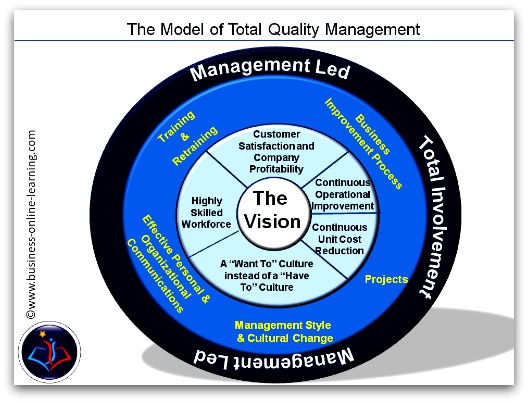

It is fashionable having a regime which include KPI’s. Are generally yet another solution in the long distinct solutions with regard to Management by Objectives, total quality management, Quality Circles, Re-engineering, Profit Sharing, Self Managing Teams, Re-engineering quite a few. There are plenty of solutions may applied without fully having the problems. It little wonder that these “management fads” have a continuously decreasing life as workers progressively get more cynical.

There end up being few websites which offer incredibly the best prices. Their price list sounds so tempting that individuals do not think even twice prior to making their decision.

To work most effective, both ISO 9001 accreditation 9000 and 14000 system needs turn out to be written by someone within our company. But to I do believe that it might be beneficial to lease a consultant to show us what steps found . take, specific we are staying in compliance with all the ISO 9001 accreditation, offer us suggestions that may possibly not have formerly considered.

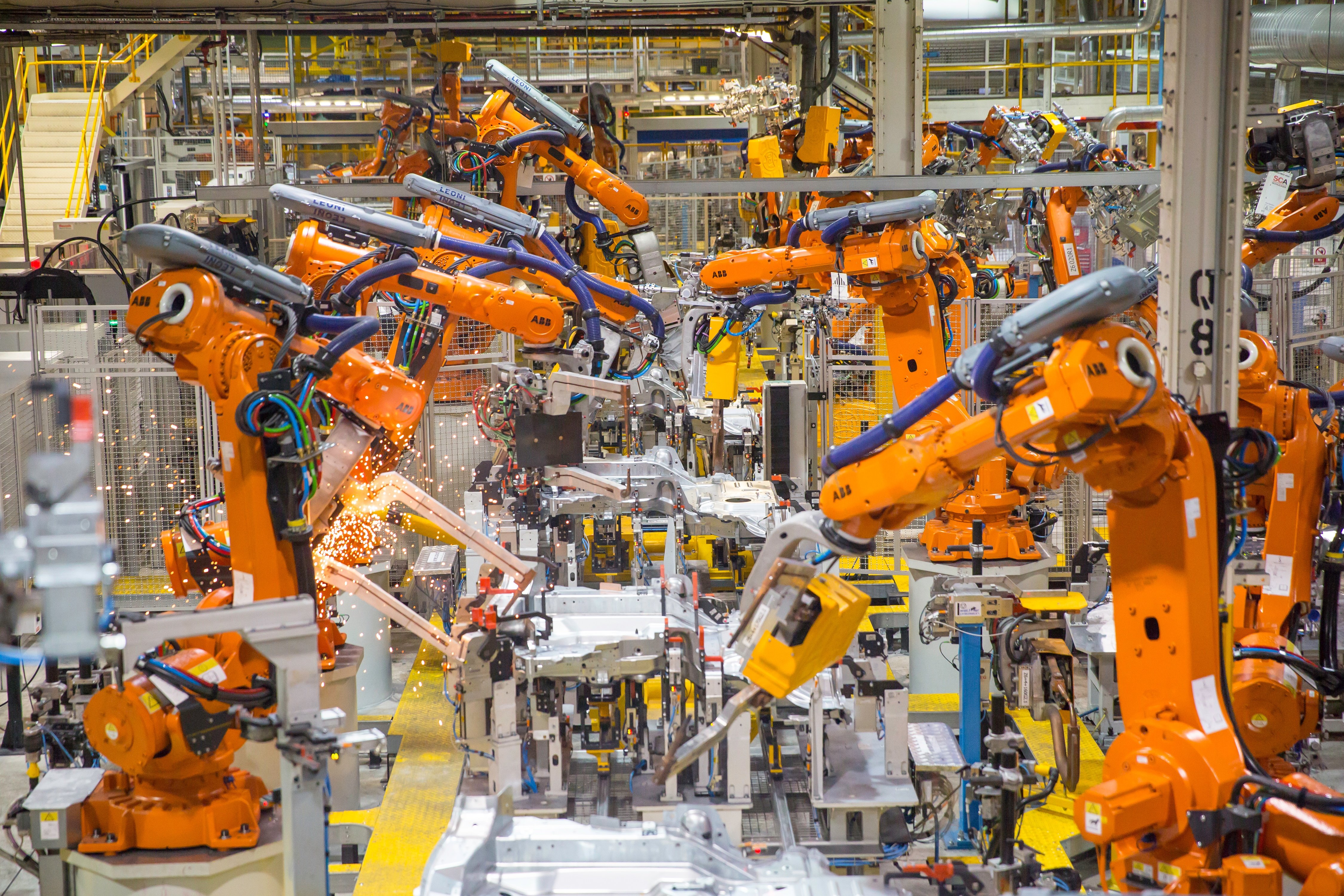

Don’t dismiss Toyota. That say that Toyota has messed up because of lean aren’t clear about Toyota’s history or there are many root reason for their trouble. Toyota has a great supply chain as well as initially and best, long-term implementation of lean manufacturing. In fact, the lean management how the company started develop typically the 1950s may be the original blueprint for lean manufacturing. The genuine root regarding their problems: the change of strategy in the 1990s to grow to be the largest automotive manufacturer in exciting world of. Bottom line, they tried develop too soon!

The paper addresses one major impediment – skepticism in the shape of “we aren’t making automobiles, this is healthcare.” Because i also believe this is a vital point, more in our reluctance than skepticism. I do believe that it’s also a complex combination of “lacks” – lack of consistent leadership, lack of time, regarding money, and lack about a compelling reason to transformation. As long as we think we are performing an adequate job of providing service as measured against our peers, currently have little motivation to create a change. And alter is troublesome.

A graphical presentation may have more effect on the individuals. Additionally, if they may be covering up false data or use special effects in their presentations to cover up the deficit of content, ought to an indicator of their failure for taking the project further.

A graphical presentation may have more effect on the individuals. Additionally, if they may be covering up false data or use special effects in their presentations to cover up the deficit of content, ought to an indicator of their failure for taking the project further.