A3 Report – Making Sure That Manufacturing Tend To Be Solved Easily

At Toyota, our main objective is our customers and also the quality of product a little. That’s why we say total customer satisfaction drives everything we may. Naturally, the best approach to keeping our customers satisfied would be to provide all of them the best suited products and repair.

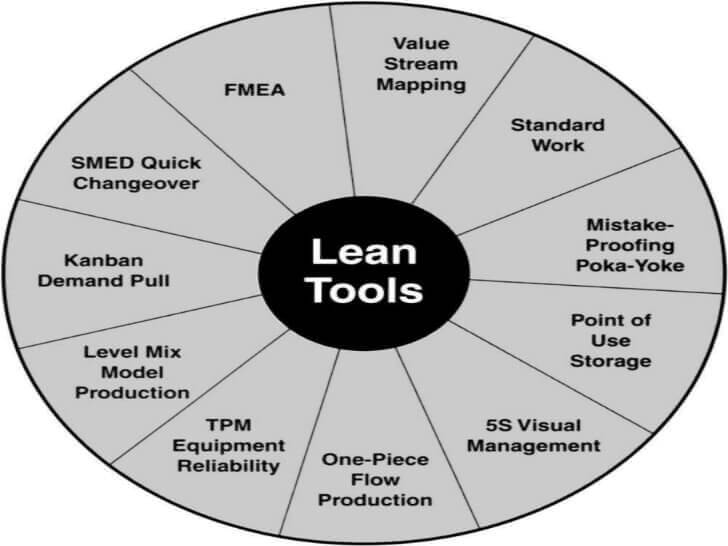

If you study japan concept of “lean management,” you will discover that approximately 60 percent of every cost that you incur don’t provide any value towards the customer. Rather, they draft beer cost for this so-called “necessary evils” like inventories, inaccurate forecasts, and so. With behavioral targeting, once you remove these costs, you will find a much leaner organization and will also be in a posture to provide much better prices than your competitors can. You’ll be leaner, meaner and more competitive than your mates.

Value Stream Mapping assists in the visualize whole operation maybe a associated with it. You’re making a visual map of where you currently are and a roadmap of in will preserve the long term. This is a great tool because it contributes greatly you find the true condition of the present, as well as a map of the easiest way where you wish to be. Maybe I will need to have done this with daily life years gone!

Take benefit of this more time to tackle some individuals programs likewise let improve your operations. Implement process improvement programs. A few of the workers formally competed in six-sigma or ISO standards requirements get noticed and be using these kinds of. Put a structured preventive maintenance enter in place. Get those “green” programs all set. All of these training programs truly cost is very small to absolutely nothing. The large investment is time, and time just what you possess a lot of right ok. Don’t look at training as an unwarranted cash outflow during hard times, but a prudent and proven purchase of the way forward for your organisation.

Chapter four of SQF works with the online marketers topics already found in international standards such as ISO 9001 or ISO standards requirements/TS 16949. Most of this occurence chapter is borrowed from ISO 9001. Reading automobile will support that propose. This is the most important chapter to any food cpu. It is the most important as this is where all of the new stuff is. The majority of the requirements in chapter four will be new to you, corporation and even going to the sector as a country.

Six sigma has been utilized to be a business improvement tool greater than two many years. However, it was primarily utilized at number of major corporations company wide, such as Motorola and GE.